Designed and manufactured by Alberta Petroleum Industries Ltd., the 7 1/16” – 5000psi SRC BOP is constructed to meet the conditions required of snubbing operations. No longer will companies be forced to run equipment designed for drilling or work-over activity in their snubbing operations.

Our product has evolved from years of hands-on experience in the BOP manufacturing, service and repair industry Its design has been driven by a desire to provide a product that is built specifically to meet the rigors of snubbing operations and continuous working cycles under pressure. The SRC utilizes a round ram block design, ideal for such an environment. Incorporating Alberta Petroleum Industries’ patented technology the SRC offers a solution that is second to none in terms of safety, performance, reliability and cost-effectiveness.

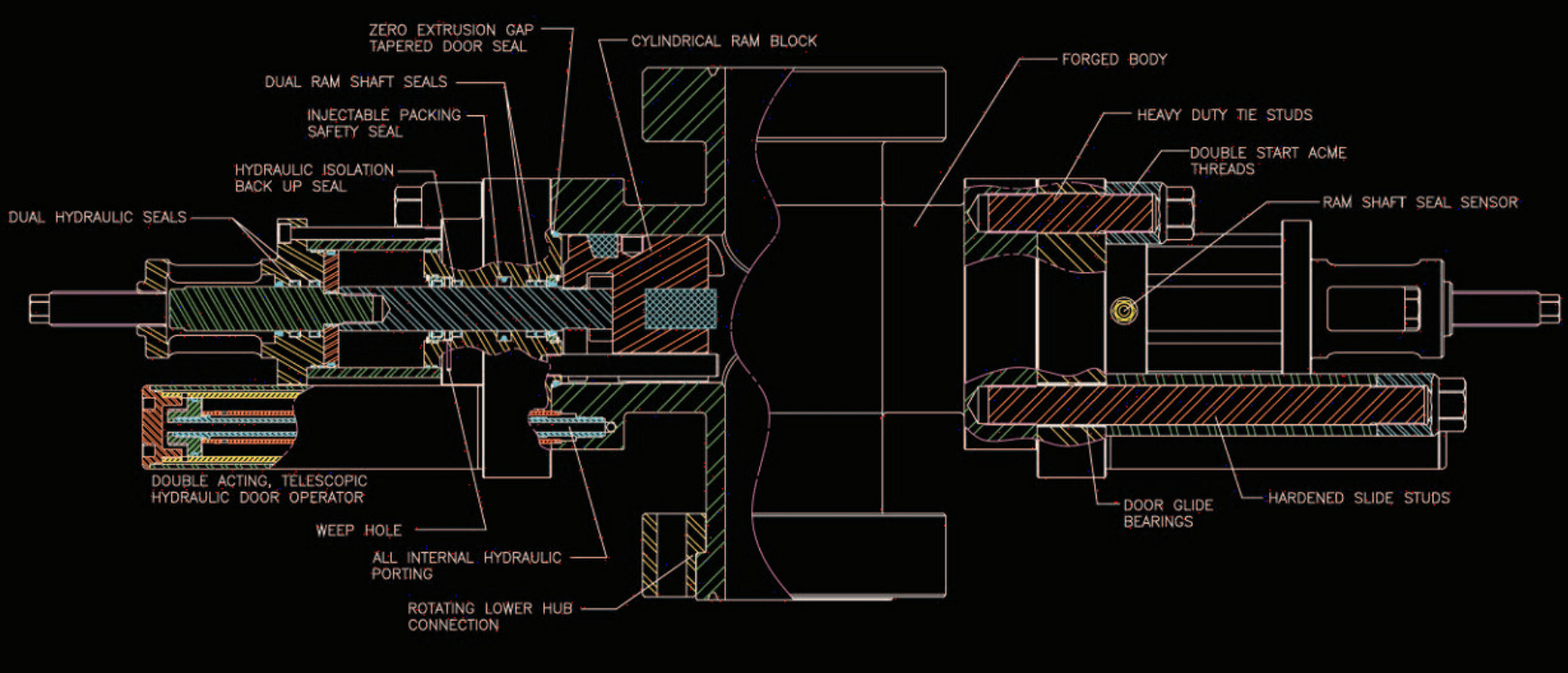

At approximately 1810 lbs dry, the unit eliminates heavy cast components but retains its strength and durability through use of a high quality forged body.

The unit incorporates our patented seal failure identification technology, which leverages primary and back-up seals as well as a safety injection shut-in system. The back-up seal configuration allows operations to continue without the need to inject the packing safety seal, thereby saving the safety system for emergencies…the original intent of the injection system design.

The Door Seal utilizes a zero extrusion gap, tapered bore seal design to ensure a reliable seal with extended cycling capability. The back up ring is made from a high modulus material which interferes with the tapered bore ensuring the extrusion gap is perfectly zero. This configuration provides a solid low pressure seal with high pressure re-enforcement.

Our specially designed Block Guide ensures the blocks will drop directly into place each time.

Doors return to the same position every time after they are opened and closed. The hydraulically operated doors are fitted with bearings and mounted on extended, polished and hardened door studs to ensure smooth operation and positioning accuracy.

Each sealed component may be easily accessed and readily serviced in the field to minimize down time.

Our patented dual acting, telescopic hydraulic door operator actuates the door and ram assemblies while keeping the fluid channels internal. This eliminates the need for hinge bores and external components and piping common to our competitors units, thereby lessening damage, wear and leakage points in the system.