Alberta Petroleum Industries has begun manufacturing its DOM Annular BOP entirely in Canada! This is truly a MADE IN CANADA product! From the original engineering and design, to castings, machining, QC inspection, final testing and application of the API 16A monogram, this is a Canadian made product.

The DOM comes in two configurations

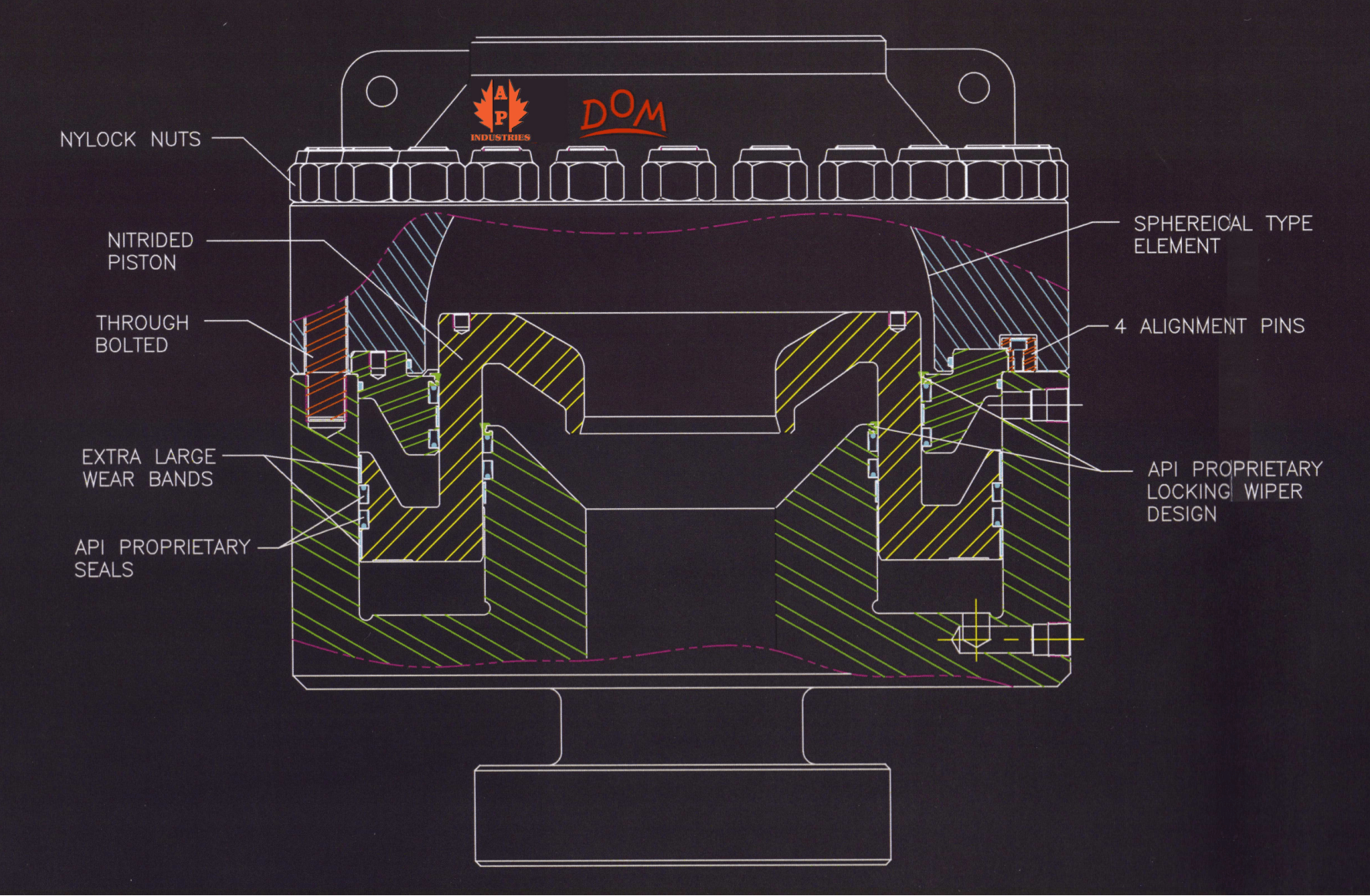

1) The DOM Snubbing spherical, utilizing our patented wiper seal technology (Patent #’s CAN 2413112, US 2634439) which greatly enhances it functionality in snubbing operations.

2) The DOM-SS is a replica and interchangeable with the venerable Shaffer Bolted Top Spherical API 16A 4th Edition

As a long standing API 16A and Q1 accredited facility, our products are manufactured in accordance with those guidelines. The DOM is designed and manufactured to API 16A 4 edition.

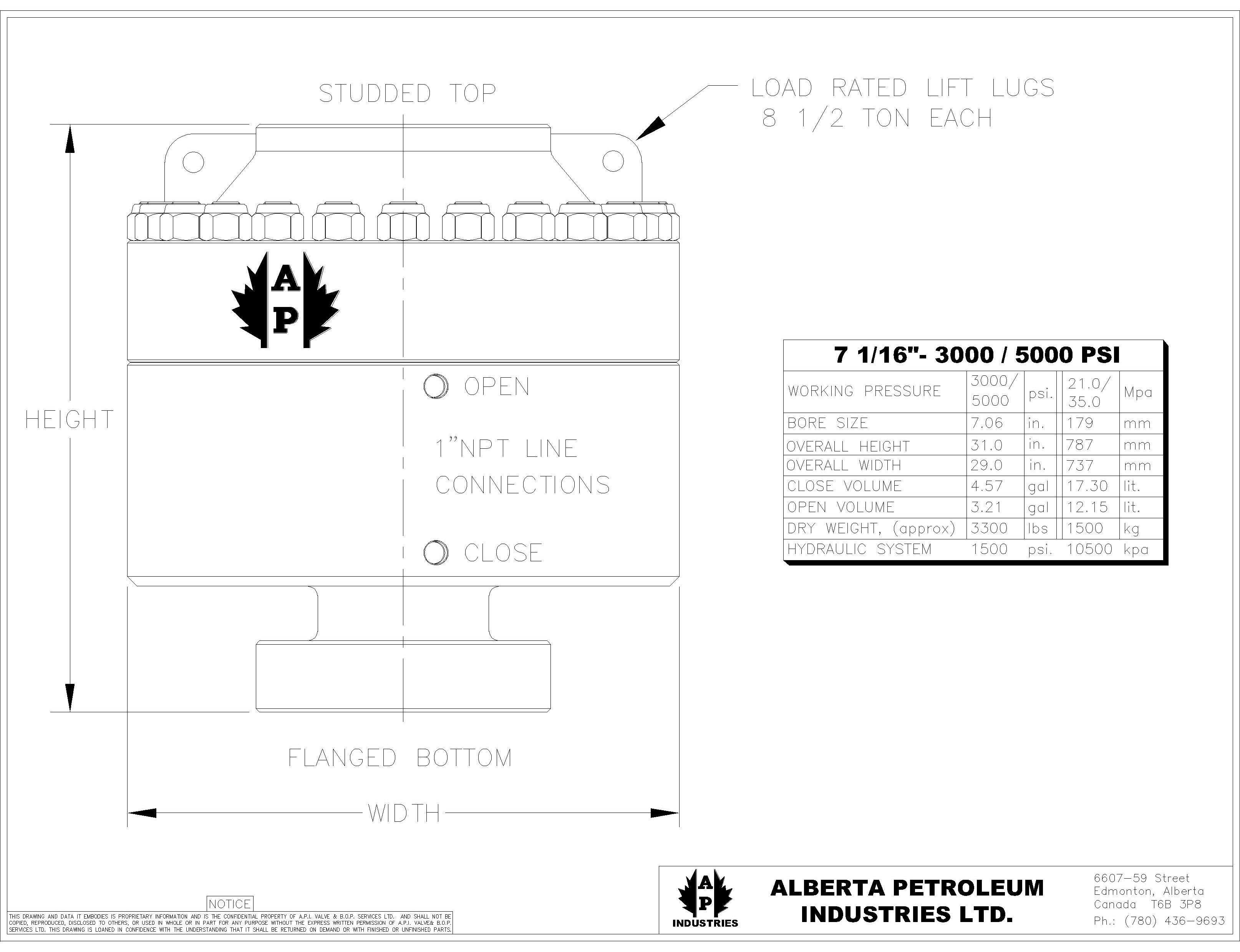

The DOM is currently offered in 7 1/16 3,000 PSI or 5000 PSI configurations, with options of nitrile or natural rubber packing elements.

The longer rectangular seal prevents damage caused by rolling in the groove, increasing seal reliability and life.

Profile locks into groove and is retained by the seals to prevent it from extruding.

Provides longer life and added stability for the piston.

Offer a strong and reliable connection that will not loosen accidentally. Simple removal with overhead rigging, allowing easier bag changes with no internal threads to stick or gall up.

These coatings improve wear life of the piston, meaning longer intervals between major repairs. Also provides corrosion resistance. Either Nitriding or Teflon coating is an option.

Positive alignment and improved retention of the adapter ring which prevents flexure and binding during lid removal. Allows for hassle free element changes.

| Specification | API 16A, 4th Edition |

| Nominal Bore Size | 7 1 / 16 " 9" as per API 6A, 20th Edition | Maximum Working Pressure | 3000 PSI 5000 PSI |

| Nominal Dimensions | 7 1/16 5000: Height - 3 1 ", Diameter - 29.0" : Height - 33", Diameter - 35 1 / 2 " |

| End Connections - Upper | 7 1 / 16" 5000(R46) Studded, Studded |

| End Connections - Lower | 7 1 / 16" 5000(R - 46) Flanged, Flanged |

| Metallic Materials Temperature Rating | Code T - 20: -20°F to 250°F(-29°C to 121°C) |

| Wellbore Elastomeric Materials Tenperature Rating | Code AA. - 15°F to 180°F(-26°C to 82°C) |

| Non - Wellbore Elastomeric Materials Tenperawre Rating | Code AA. - 15°F to 180°F(-26°C to 82°C) |

| Closure Bolting | NACE MR - 0175 - 2003 compliant bolting & nuts on body correction |

| Application | Land based drilling & service rigs |

| Element | Determined bv Customer |

| Paint Details | Determined by Customer |

| Seal Configuration | Snubbing or Standard |

| Post Delivery Contract Arrangements | Regulatory and Safety Requinements |

|---|---|

| Service on warrarty claims (12 months) | NACE MR0175 |